Test cell

TestplatformNewly build test cell in 2003 of the U-type (vertical intake and exhaust).

Comply with latest environmental requirements and accomodate engines up to 75.000 lbs.

This testcell is the result of thouroughly aerodynamic and accoustic studies in cooperation with the KU Leuven University. The test cell is correlated and approved by Pratt & Whitney.

Testrun verification and compliance with the manufacturer's requirements. Final inspection will include a boroscope and walk-around inspection. |

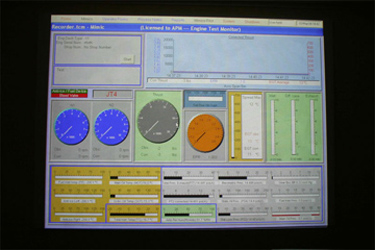

Control roomThe control room 6m by 6m is completely noise isolated. |

|

|